A filthy occupation: leather-tanning in Morocco

-

Rainbow wares: leather goods are a popular holiday souvenir from Morocco. In many of the narrow souks in the old town centres, there are alleys full of leather shops. But you can also buy the brightly coloured shoes, belts, bags and co. directly from the leather factories. There, animal skins are still processed according to traditional methods. Working conditions in the tanneries are correspondingly tough -

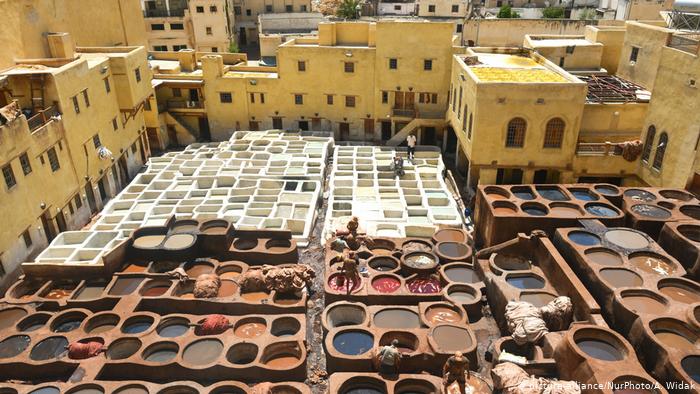

Town within a town: a view from the balcony gives tourists in the old town of Fez a glimpse inside the world-famous Chouara leather factory. Right its heart, the work goes on here as it has for centuries – requiring natural materials and full physical exertion. The leather is cleaned, soaked and dyed in countless pits. It takes about a year to turn animal skin into leather -

Aided by a wooden wheel: one worker stacks the furs on a wall, another cleans them in a basin. Leatherworking has a long tradition in Morocco. Almost two billion square metres of leather are processed every year, mostly leftovers from the food industry. Nevertheless, the Chouara factory is something special: recommended by many travel guides, it is located in the middle of the old town of Fez -

Beautiful stench: seen from above, the filled clay basins in the Chouara tannery look like a huge paint box. But the photo is deceptive. What is colourful to the eye, is unpleasant to the nose. This is mainly due to the processed bird droppings that are used for staining in the tannery. Tourist guides therefore offer sprigs of peppermint, which you can hold under your nose -

Barefoot in bovine urine: this worker is working without any protective clothing. He kneads the leather piece in the lye until it is soft enough. The Chouara tannery in Fez still uses old methods and ingredients like bovine urine and pigeon droppings. Modern tanneries use chemicals, with the usual negative consequences for the environment -

Cat with leather hides: animal hides hang like rags on the dirty walls of the houses in Fez tanners' quarter. Once tanned, they have to dry in the sun before being processed further. Chouara leather factory is famous for its age-old craft – it has even qualified as a UNESCO World Heritage site -

Using their bare hands: tanning is hard manual labour. The skins are first soaked for a few days in vessels full of bovine urine, lime, water and salt before they are dried. They are then soaked in lye again and dried. Dyeing is done – at least in the Chouara in Fez – with natural ingredients such as saffron, indigo and poppy seeds -

Squatting to work: will this be a bright yellow bag one day? Two workers pull a dyed animal skin taut on the floor to dry it. For the tourists, the sight of the old craft is interesting and full of nostalgic charm; for the tanners, however, the daily grind in dirt and stench is anything but easy. Hygiene conditions are poor -

Work till you drop – a lifetime for the leather factory: this Moroccan has been working in tanneries for around sixty years. At 80, he is the oldest employee in the Chouara tannery in Fez. Many Moroccan families are indeed dependent on the income of the elderly. That said, youth unemployment in the cities is over 30 percent

https://qantara.de./en/node/20816

Link

To all image galleries